TG Tube: The Hidden Hero in Cutting-Edge Technological Advancements

In the ever-evolving world of technology, certain innovations quietly revolutionize industries without garnering the spotlight they deserve. One such unsung hero is the TG Tubee. While it may not be a household name, the TG Tubee is pivotal in enabling cutting-edge advancements across various sectors, from aerospace and automotive to healthcare and renewable energy. This article delves into the significance of TG Tubee, its applications, and why it is a cornerstone of modern technological progress.

What is TG Tube?

TG Tube, short for Thermo-Gradient Tube, is a specialized component designed to manage thermal gradients efficiently. It is engineered to control heat transfer, maintain temperature stability, and enhance the performance of systems operating under extreme conditions. The tube’s unique design and material composition allow it to withstand high temperatures, pressure, and corrosive environments, making it indispensable in advanced technological applications.

At its core, the TG Tubee is a material science and engineering marvel. It is often constructed from high-performance alloys, ceramics, or composite materials that offer exceptional thermal conductivity, durability, and resistance to wear and tear. These properties make it a critical component in systems where precision and reliability are non-negotiable.

The Science Behind TG Tubee

The effectiveness of TG Tubee lies in its ability to manage thermal gradients—variations in temperature within a system. Thermal management is crucial in many industries because excessive heat or uneven temperature distribution can lead to system failures, reduced efficiency, and even safety hazards.

TG Tubees are designed to:

- Dissipate Heat Efficiently: TG Tubees prevent overheating and ensure optimal performance by channeling heat away from critical components.

- Maintain Temperature Uniformity: They help stabilize temperatures across a system, reducing thermal stress and prolonging the lifespan of equipment.

- Enhance Energy Efficiency: By optimizing heat transfer, TG Tubees contribute to energy savings and reduce operational costs.

The science behind TeG Tubes involves advanced thermodynamics, fluid dynamics, and material engineering. Its design often incorporates features like microchannels, heat fins, or phase-change materials to maximize its thermal management capabilities.

Applications of TG Tube in Modern Technology

The versatility of TeG Tube makes it a key player in numerous industries. Below are some of the most prominent applications where TG Tuebe is driving Innovation:

1. Aerospace and Aviation

In aerospace, where components are subjected to extreme temperatures and pressures, TG Tuebes are used in engines, thermal protection systems, and avionics. They help manage the intense heat generated during flight, ensuring the safety and reliability of aircraft.

2. Automotive Industry

Electric vehicles (EVs) and high-performance cars rely on TG Tuebes for battery thermal management and engine cooling. TG Tuebes enhance vehicle performance, extend battery life, and reduce emissions by maintaining optimal operating temperatures.

3. Renewable Energy

TG Tuebes manage heat generated by energy conversion processes in solar power systems and wind turbines. They play a crucial role in improving the efficiency and durability of renewable energy systems.

4. Healthcare and Medical Devices

TG Tuebes are integral to medical equipment like MRI machines, laser systems, and diagnostic devices. They ensure precise temperature control, essential for accurate diagnostics and patient safety.

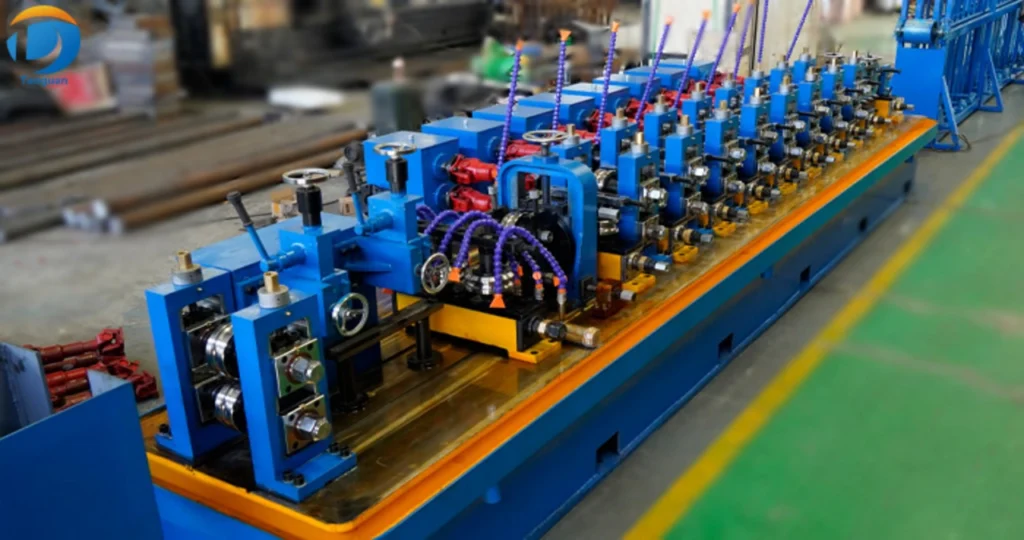

5. Industrial Manufacturing

In manufacturing processes that involve high temperatures, such as metal forging or chemical production, TG Tubes help maintain consistent temperatures, improve product quality, and reduce downtime.

6. Electronics and Telecommunications

As electronic devices become smaller and more powerful, managing heat dissipation is a growing challenge. TG Tuebes are used in smartphones, computers, and telecommunications equipment to prevent overheating and ensure reliable performance.

Why TG Tube is a Game-Changer

The importance of TG tuebes in modern technology cannot be overstated. Here are some reasons why it is a game-changer:

1. Enabling High-Performance Systems

allow systems to operate at peak performance by effectively managing thermal loads. This is particularly critical in industries like aerospace and automotive, where even minor inefficiencies can have significant consequences.

2. Enhancing Safety and Reliability

TG tub contribute to equipment safety and reliability by preventing overheating and thermal stress. This is especially important in healthcare and aviation, where equipment failure is not an option.

3. Driving Sustainability

TG Tubs play a vital role in improving energy efficiency and reducing waste. Renewable energy systems, for example, help maximize energy output while minimizing environmental impact.

4. Supporting Innovation

The demand for more efficient and compact thermal management solutions grows as technology advances. TG Tubs address these challenges and enable the development of next-generation technologies.

The Future of TG Tube

The future of TG Tue is bright, with ongoing research and development focused on enhancing its capabilities. Some emerging trends include:

1. Advanced Materials

Researchers are exploring new materials like graphene and carbon nanotubes to create TG Tues with even higher thermal conductivity and durability.

2. Miniaturization

As devices become smaller, there is a growing need for compact thermal management solutions. Miniaturized TG Tues are being developed to meet this demand.

3. Smart Thermal Management

Integrating sensors and IoT technology into TG Tues enables real-time monitoring and control of thermal conditions, further improving efficiency and performance.

4. Sustainability Focus

Efforts are underway to make T Tubes more environmentally friendly by using recyclable materials and reducing energy consumption during manufacturing.

Challenges and Opportunities

While Tube technology has come a long way, challenges still exist. These include:

- Cost: High-performance materials and advanced manufacturing processes can make Tubes expensive.

- Complexity: Designing and integrating TG Tubes into complex systems requires specialized expertise.

- Scalability: Scaling up production to meet growing demand while maintaining quality is challenging.

However, these challenges also present opportunities for Innovation. Companies that invest in research and development can gain a competitive edge by creating more efficient, cost-effective, and sustainable TG Tube solutions.

Conclusion

TG Tube may not be a household name, but its impact on modern technology is undeniable. From aerospace and automotive to healthcare and renewable energy, it drives Innovation and enables advancements that shape our world. As technology continues to evolve, the importance of efficient thermal management will only grow, making TG Tube an indispensable component of the future.

By understanding the science, applications, and potential of TG Tube, we can appreciate its role in cutting-edge technological advancements and look forward to the exciting developments it will enable. Whether you’re an engineer, a tech enthusiast, or simply curious about the innovations shaping our world, TG Tube is a topic worth exploring.

This article has provided a comprehensive overview of TG Tube, its significance, and its applications. As industries continue to push the boundaries of what is possible, TG Tube will remain a critical enabler of progress, proving that sometimes the most impactful innovations are the ones working behind the scenes.

FAQs About TG Tube: The Hidden Hero in Cutting-Edge Technological Advancements

1. What is a TG Tube, and how does it work?

A TG Tube, or Thermo-Gradient Tube, is a specialized component designed to manage thermal gradients by controlling heat transfer and maintaining temperature stability. It works by dissipating heat efficiently, maintaining uniform temperatures, and enhancing energy efficiency in systems operating under extreme conditions. Its design often incorporates advanced materials and features like microchannels or heat fins to optimize thermal management.

2. What industries benefit from TG Tube technology?

TG Tube technology is widely used across various industries, including:

- Aerospace and Aviation: For engine cooling and thermal protection systems.

- Automotive: In electric and high-performance cars for battery and engine thermal management.

- Renewable Energy: In solar power systems and wind turbines to improve efficiency.

- Healthcare: For precise temperature control in medical devices like MRI machines.

- Electronics: To prevent overheating in smartphones, computers, and telecommunications equipment.

3. Why is TG Tube considered a game-changer in modern technology?

TG Tube is a game-changer because it:

- Enables high-performance systems by managing thermal loads effectively.

- Enhances safety and reliability by preventing overheating and thermal stress.

- Drives Sustainability by improving energy efficiency and reducing waste.

- Supports Innovation by addressing the growing demand for efficient thermal management in next-generation technologies.

4. What are the future trends in TG Tube technology?

The future of TG Tube technology includes:

- Advanced Materials: Using graphene and carbon nanotubes for higher thermal conductivity.

- Miniaturization: Developing compact TG Tubes for smaller devices.

- Smart Thermal Management: Integrating sensors and IoT for real-time monitoring.

- Sustainability: Using recyclable materials and reducing energy consumption in manufacturing.

5. What challenges does TG Tube technology face, and how can they be addressed?

Challenges include:

- Cost: High-performance materials and advanced manufacturing processes can be expensive.

- Complexity: Designing and integrating TG Tubes into complex systems requires specialized expertise.

- Scalability: Scaling up production while maintaining quality is difficult.

- These challenges can be addressed through continued research and development, investment in innovative materials, and collaboration between industries to create cost-effective and scalable solutions.